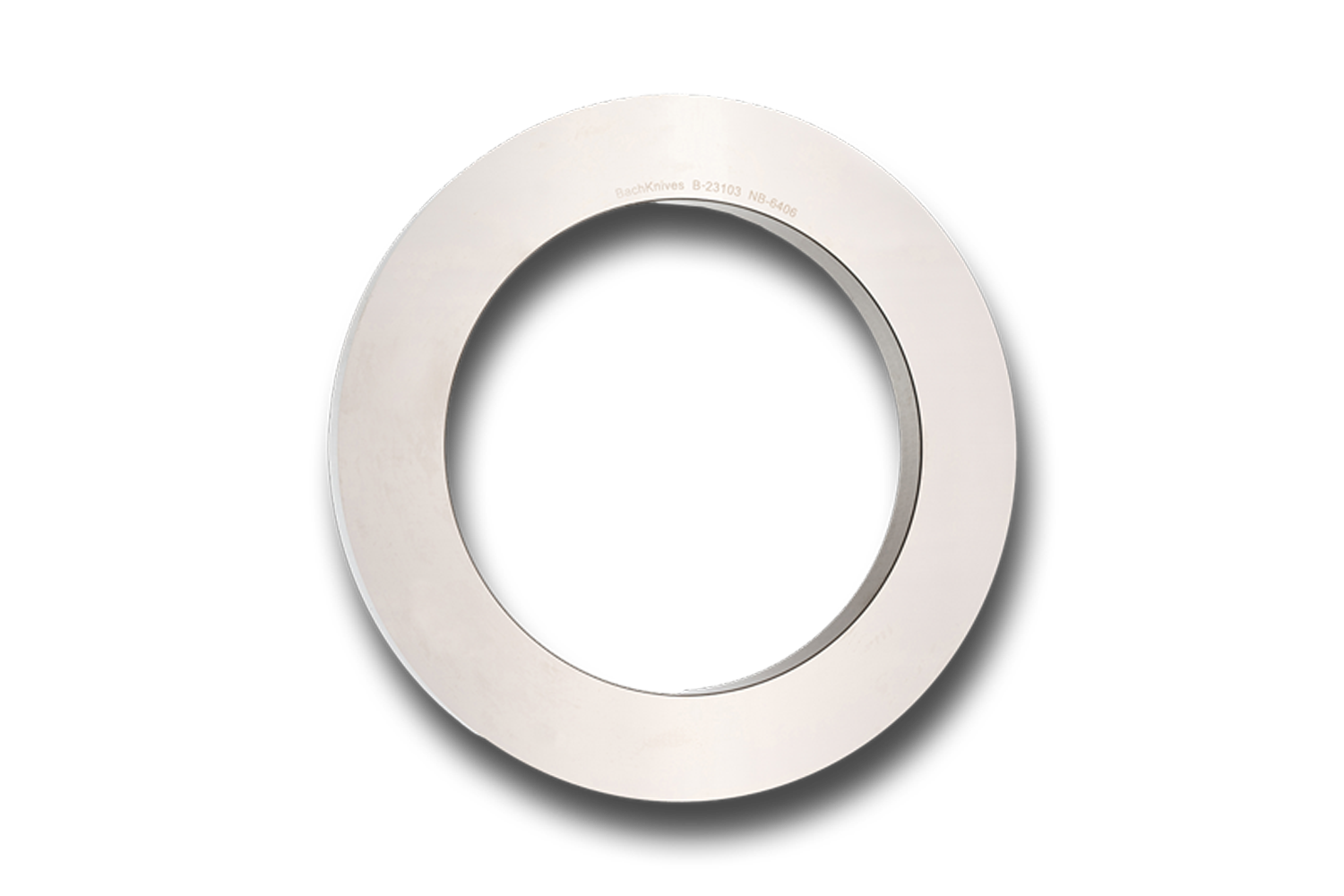

Our slitter knives are manufactured using state of the art materials and the latest technology and production techniques. We start with the highest quality European forged material, vacuum harden and triple temper to Rockwell held to ±1, then finish with lapping and polishing to produce the finest metal slitter knives. Our production facilities allow us to produce knives with a flatness, parallelism, surface finish and tolerance unmatched by our competition with 100% inspection before shipping.

Our shear and slitter knives are used to cut a wide variety of materials from 0.0003″ foil to greater than 2″ thickness. We offer the best-suited and successful grades for slitting and shearing HSLA, AHSLA, Duplex©, stainless steels, nickel alloys, copper, brass, titanium, indium aluminum, hot rolled steels, phosph, bronze, clad, and laminated metals.